This gallery contains 3 photos.

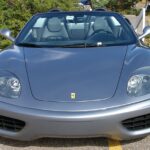

Ferrari Club members at the Manor House Car Show

I have been thinking of a name for the new car and I came up with Bella. A great Italian name for a great Italian car. Due to other projects around the house I have not found much time to sit down and tune Bella. Since I have been neglecting her I bought a few “presents”. At T. Rutlands Ferrari parts I found some Pommello Fissaggio Coperchio and Fascetta. That is Italian for Air Box Nuts and fuel/vacuum line clamps. Sounds much better in Italian! The air box nuts are often lost and the car arrived with only one of the original fasteners. Also since I plan on going through the fuel and vacuum system I will replace worn clamps as I go with original replacements.

I have been thinking of a name for the new car and I came up with Bella. A great Italian name for a great Italian car. Due to other projects around the house I have not found much time to sit down and tune Bella. Since I have been neglecting her I bought a few “presents”. At T. Rutlands Ferrari parts I found some Pommello Fissaggio Coperchio and Fascetta. That is Italian for Air Box Nuts and fuel/vacuum line clamps. Sounds much better in Italian! The air box nuts are often lost and the car arrived with only one of the original fasteners. Also since I plan on going through the fuel and vacuum system I will replace worn clamps as I go with original replacements.

The Italian references you see throughout the site are due to the fact that Ferrari’s are Italian (duh!) and to illustrate the fun involved with translating the owners manual, shop manual, and parts diagram. Luckily all these were included with the car. The owners manual is actually the original with the original binder that came with the car! The books are translations from Italian, and sometimes the translations are a little rough. More reason to learn Italian! It will also come in handy when I go visit Bella’s homeland.

I took my youngest son Tyler out for a spin in the car today and we stopped by the Cars and Coffee at The Great Indoors at Park Meadows. There was two other Ferrari owners there and one brought his 328. Several people checked out the car and were impressed, especially with the condition of the paint and the leather interior. After we had coffee and checked out the cars we headed over to GiGi’s (great grandmother) house and showed her the new car. She has been looking forward to getting to ride in the car and even dressed up in her Sunday finest for the occasion!

The first stop on my search for parts was Scuderia Rampante in Boulder. I found the smog pump line here for a third the price and they are going to be able to fabricate the t-fitting (for a lot less than $475). If you are a Ferrari owner this place is the real deal. If your Prancing Horse is sick or in need of TLC they know what to do.

So the fun begins! I pulled out the smog pump today to replace the pump and all of the lines. I was able to find a replacement air pump at NAPA. For anyone looking for a replacement air pump this is a great option, part #NAP 51212. When I removed the air pump it was identical to this one, so Ferrari must buy their smog pumps from NAPA! (or it has already been replaced) If you do get the part from NAPA though make sure the back is stamped with the number 7817872. My replacement looked identical but had a different number stamped on the back. The only difference was that the pulley bolts and air outlet fitting bolts were a size larger, minor inconvenience, but annoying still. Ferrari wants over $800 for the air pump and $750 for the lines and metal t-fitting (the t-fitting is $475 alone). Needless to say I am going to try to source some cheaper parts!

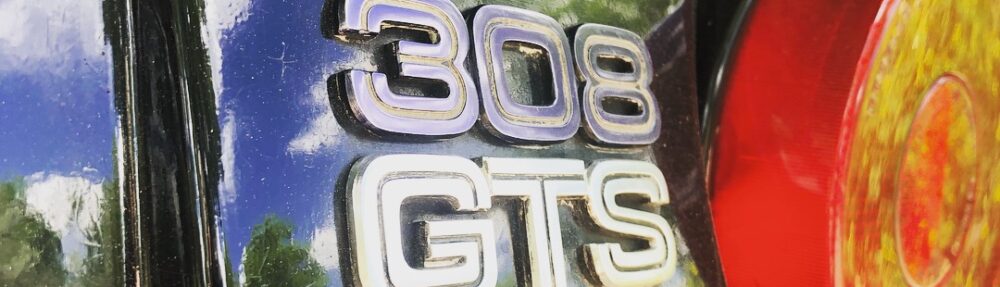

Since we live in Colorado I unfortunately have to have the car pass emissions. In order for this to happen the carbs have to be re-jetted for altitude and tuned. Also the smog pump seized on the car so that will have to be replaced also. I also want to do a compression check, cylinder leak down test, and fine tune the timing before I tackle the carbs.

When the car was sold to Grand Prix Classics the owner drove the car for fun. The only change he made was to the wheels. He installed the current Etoile wheels on the car since the previous set was cracked (probably from racing!) He sold the car to purchase an offshore boat. The car, with 58,032 miles, was off to the fifth owner…in Michigan. The car was given a major service in June of 1999 and at 61,929 miles the car was sold again and resided in Wisconsin. The owner in Wisconsin did not drive the car often and put about 500 miles on the car before selling the car to me. So that leaves me as the seventh owner of this beautiful car. The car has been well cared for and always kept garaged. This is evident by the fact that it still has the original paint and interior.

My assistant mechanic John stopped by for a spin in the car, since they were somewhat disappointed during the original unveiling. We drove the car around the neighborhood and filled her with fuel. She drove quite nicely minus running rich and some hiccups at 3000 RPM which should be worked out during the tuning and re-jetting of the carbs.

As I wrote about earlier the car came with a “baby book” including all records and repairs. The car was purchased in January of 1980 from Ferrari of San Diego and was delivered in March of 1980. At 11,000 miles the car was sold through Ferrari of La Jolla. The second owner added the front spoiler to make the car look like a Euro version. He also installed the rear spoiler, which was a factory option. The engine was given new cams and re-jetted to european specs. The suspension was also stiffened. A custom Alpine stereo was installed, and a Harris Alfa-Telephone (which is still in the car) was added. The phone at that time cost $3450! All work was done at Bobileff Motorcar Company in San Diego. At 23,000 miles the car was sold to the service manager of Ferrari of La Jolla. The car was reworked and toured at track events with the local Ferrari Club. During this time the car received the fastest car of the day at Riverside Raceway during one event. Everything on the car is original except the grill, bumper, rear spoiler, and the wheels. There were approximately six other cars in the La Jolla area that were customized in a similar manner. In 1986 with 37,565 miles on the car it was sold to Grand Prix Classics.

The Proud “Co-Owners”

My head Ferrari mechanic, Tommy (my brother-in-law), stopped by today and we were able to give the car a once over. We noticed that the timing marks on the distributors were not lined up. The 1976-79 308’s used a 2-valve OHC V8 set-up with two distributors and utilizes four Weber 40 DCNF carburetors, making things a little complicated. Tommy is a heavy diesel mechanic and I also have most of my background in diesel also, so there is going to be a bit of a learning curve. After some adjusting we were able to bring the car back to life. This was definitely a relief to myself…and my wife. We of course proceeded to take the car around the neighborhood. As you can see the boys are very excited about the new toy. The car is running a little rich, but this is expected at this altitude…time for some tuning.